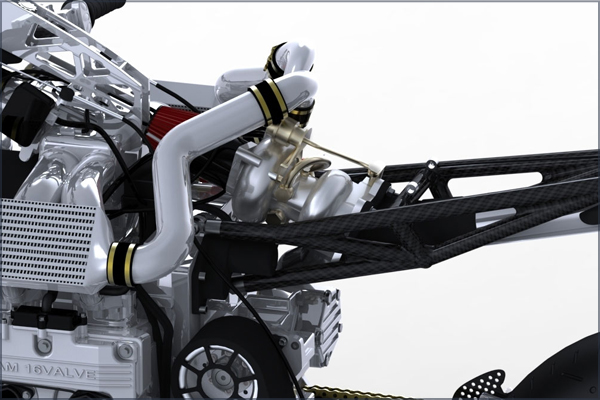

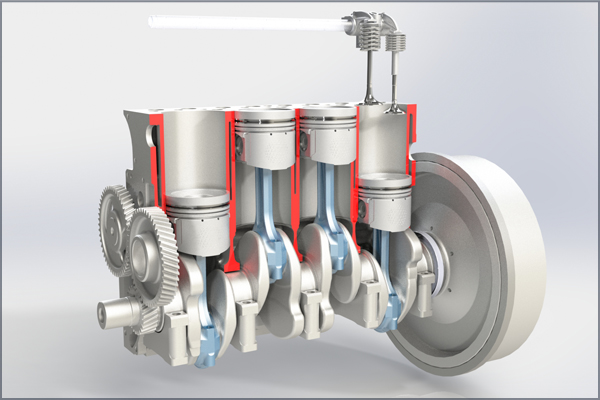

After the concept design stage, ATOM team starts the engineering work based on a deep and comprehensive knowledge of different engineering topics and areas.

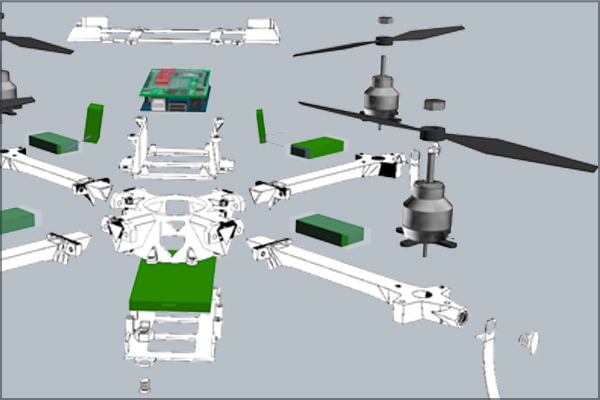

ATOM 3D engineering design stage focuses on the following factors:

- Product functionality: creating a suitable product for a specific application considering different technical factors and calculations.

- Product manufacturability: creating a product that is manufacturable when using the available production tools.

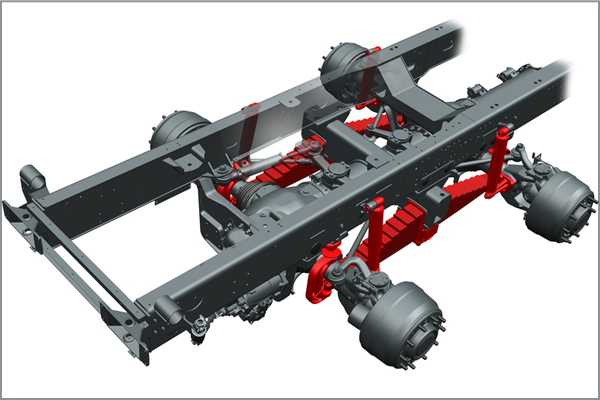

- Cost Effectiveness: ATOM team evaluate the impact of the following parameters on the total cost of the product:

- Design features,

- used materials,

- joints design,

- assembly procedure, and

- the required production processes.

ATOM team achieves the COST REDUCTION through: Design Optimization (Minimized weight with enough strength and premium manufacturability)