DFMA is a combination of two methodologies, Design for Manufacturing (DFM) and Design for Assembly (DFA).

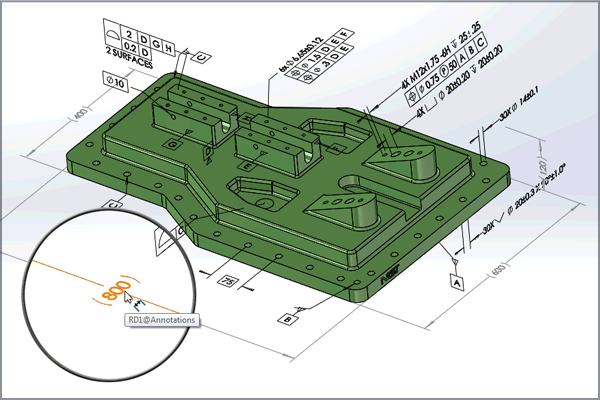

Design for Manufacturing (DFM) is the process of designing parts, components or products for ease of manufacturing with an end goal of making a better product at a lower cost. This is done by simplifying, optimizing and refining the product design. DFM techniques focus on individual parts and components with a goal of reducing or eliminating expensive, complex or unnecessary features which would make them difficult to manufacture.

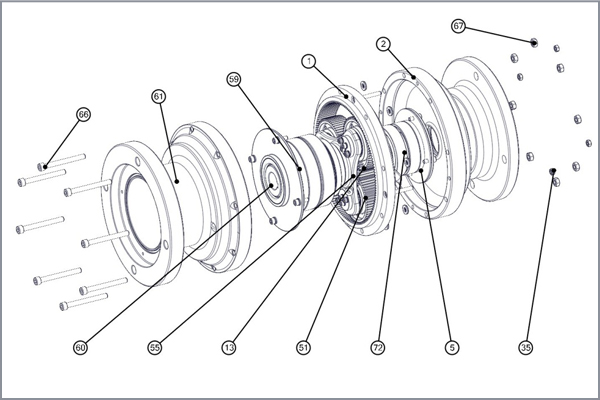

Design For Assembly (DFA) techniques focus on reduction and standardization of parts, sub-assemblies and assemblies. The goal is to reduce the assembly time and cost.

DFMA combination enables a product design to be efficiently manufactured and easily assembled with minimum labor cost. Through the use of DFM/A, ATOM can prevent, detect, quantify and eliminate waste and manufacturing inefficiency within a product design.