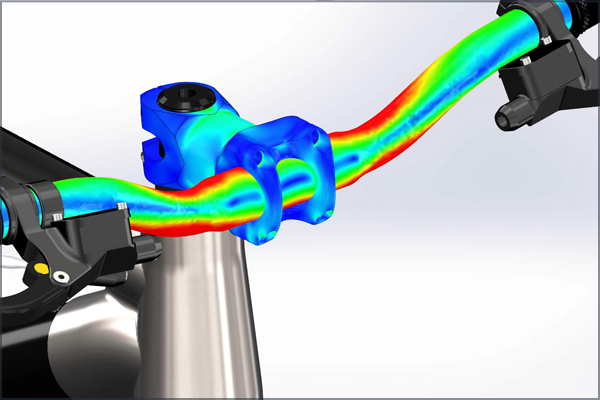

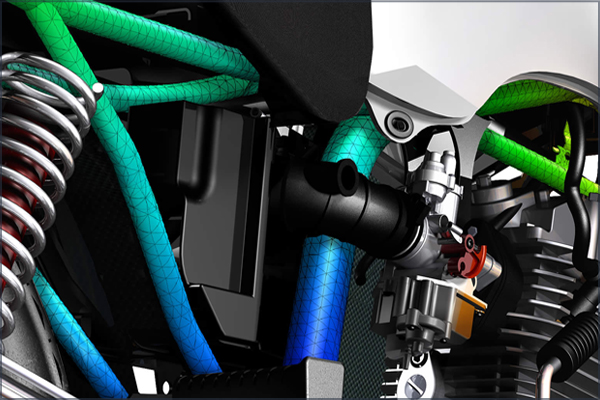

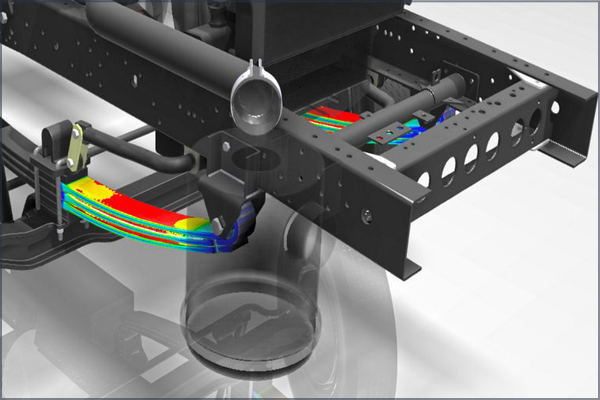

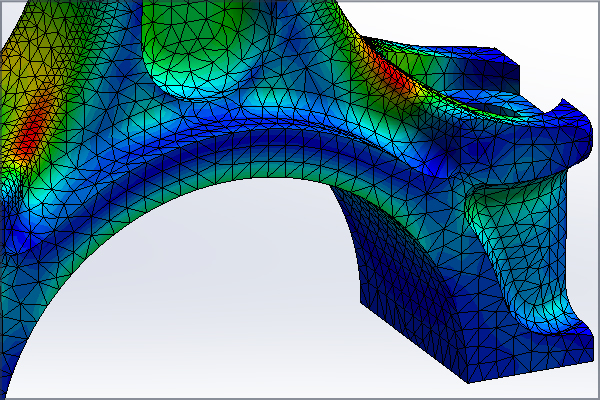

ATOM creates 3D design with parallel validation and optimization processes using 3D Finite Element Analysis (FEA). If CFD or Motion study was conducted, resultant loads can be automatically defined inside FEA study.

ATOM integrates the validation into the early design phase. By doing so, it is possible to identify design problems earlier in the process, and thus reduce the risk of failures. Also, this will allow our design team to test different scenarios before confirming one design solution.

ATOM highly qualified team has a deep knowledge to conduct the FEA using the suitable failure criteria for different material and mesh types based on the application:

- Solid mesh

- Sheet Metal (Shell)

- Composite material (Fiber)

- Composite materials (Sandwich panel)

- Structures (Beams)

- Mixed mesh