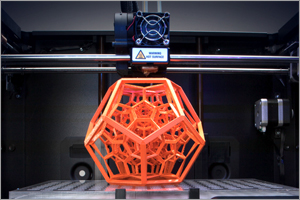

3D Printing process builds a three-dimensional object from a (CAD) model, usually by successively adding material layer by layer until the product is complete, which is why it is also called additive manufacturing,

Small parts with high geometric complexity are usually 3D printed. ATOM can offer superior printing quality for final product and good quality for prototyping.

The real integration of the 3D printing technologies into commercial production, opened the door for our customers to remain competitive with the rapid development and improvement of their products.