- Home

- Solution Consulting

Solution Consulting

At some point in time, every manufacturing company embarks upon a Digitization program, intended to leverage the latest IT and OT technologies, towards improving the performance of the company.

The process to be followed for such a program is quite standard, and well established:

- Understand the needs of the organization, and expected outcome from the program

- Understand the state-of-the-art technologies and architectures available in the market, that map on to the needs of the organization.

- Technology selection, to shortlist technologies and architectures that best align with the needs of the organization

- Write a detailed Request for Proposal (RFP) documenting all of the above, in sufficient detail, such that a vendor is able to understand the exact needs, come up with the correct effort estimate, and together, provide an accurate technical and commercial proposal.

- Identify vendors who will be able to provide the right solution and send the RFP to them.

- Evaluate the RFP responses from responding vendors and engage the correct vendor to develop and deploy the solution.

The above steps are collectively referred to as the Front-End Engineering and Design (FEED) part of a project.

So, what is the problem?

The Challenges

The challenge is that to be truly effective, points number 1 through 5 in the above process need to be done by the manufacturing company.

This is not a trivial requirement, for two reasons:

Different Needs

Every manufacturing company is different, and their needs are different too, based on size, industry vertical, geographic location, product and market situation, existing infrastructure, budget, and organization work culture.

Defining the requirements for a digitization program requires an understanding of implementations across a wide range for the above factors.

Broad Scope

A digitization program for a manufacturing company inherently contains Information Technology (IT) and Operations Technology (OT) components.

Documenting the needs and potential solution requires a thorough understanding of both IT technologies like Web Applications, Databases, Cloud/Industrial IOT/Industry 4.0 products and OT technologies like shop-floor machines, control systems (PLC/DCS, SCADA system), MES, EAM, PLM/PDM, ERP,

Large manufacturing companies have well established manufacturing IT departments, headed by a manufacturing CIO, and are quite capable of handling this task. However, small, and medium sized manufacturing companies do not have the resources required to accomplish the upstream activities that are critical to the success of the project downstream.

The ATOM FEED Consulting Process

ATOM, with its FEED Consulting Services, helps small and medium size manufacturing companies complete all the upstream tasks with the required rigor, by acting on behalf of the manufacturing company, and interacting with the vendor, to ensure that the provided solution is the right fit for the customer’s needs, budget, existing infrastructure, and organizational culture.

The ATOM FEED Consulting Process includes the following steps:

- Understand the customer environment and rate the current Maturity Level using the SIRI (Smart Industry Readiness Index) model. ATOM Consultant is a Certified SIRI Assessor (CSA) with 33 years of manufacturing experience.

- Based on the SIRI Maturity Model, recommend solutions that have the highest impact on the performance parameters of the company. Help the customer create a project.

- Hearing the project requirements from various stakeholders and plant personnel and understanding what each of them expects out of the project.

- A plant walkthrough to understand the current state of the plant from the perspective of Machines (CNC, Injection Molding, Reactors, Digestors, Extruders, Mixers), Process Automation and Control systems (PLC/SCADA/DCS), Plant Floor IT systems (MES, EAM, PLM), and Enterprise IT systems (ERP, Production Planning, Warehouse Management).

- Building a Data Dictionary – All the above systems are rich in data, and it is critical to document what data each entity produces and consumes. This also gives visibility into what data is easily available in an automated manner, and critical data elements that are (a) Missing, and hence need to be generated (b) Manually managed, and hence could be error prone or difficult to produce.

- Talking to the plant personnel to understand their current Operations Process and identify areas where improvements can be made using a Digitization initiative.

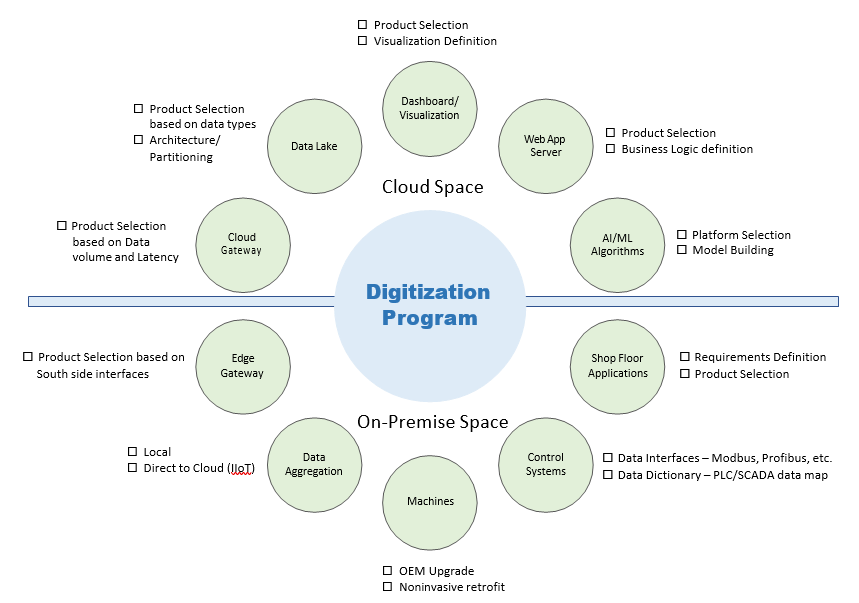

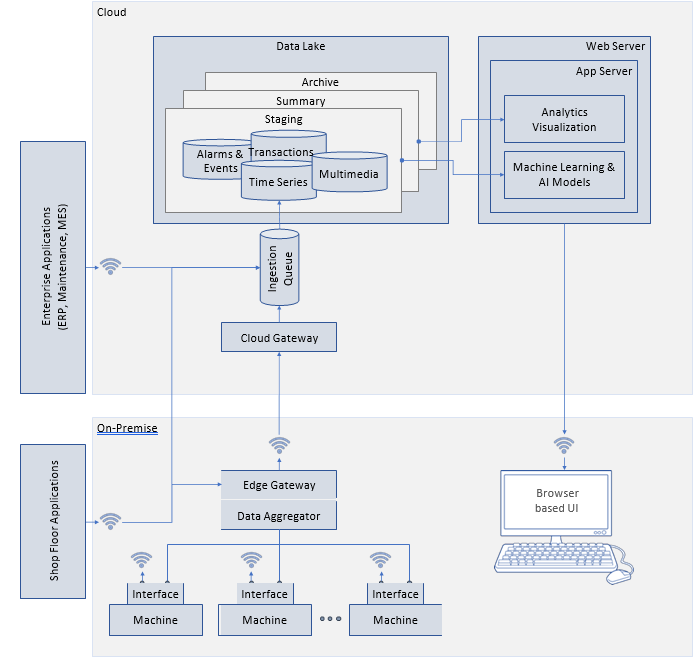

- Define a solution Reference Architecture, that is based on the above set of requirements and the state of the art for technology in the market, and organizational culture. This Reference Architecture defines the high-level components in the solutions, and makes decisions like whether the solution should be Cloud based or On-Premise, any organizational preferences for products for which they may already have an enterprise license, or a well-established and trusted vendor relationship. It breaks down the full architecture into parts that can be deployed and tested in parallel, by assigning to separate vendors. Finally, the Reference Architecture looks ahead at the future needs of the organization and ensures that it will scale elegantly as the size and scope of the organization grows in the future.

- Documenting all of the above in the form of a presentation and playing it back to the management and plant operations teams, to ensure that the right expectations from the project are set. Any expectation mismatches are resolved at this early stage and course corrections are made.

- Document all the above in the form of an RFP. At times, the RFP may be broken down into several parts, if it needs to be sent to different types of vendors, like Machine Vendor Automation Vendor/System Integrator, or an IT Product/Services vendor.

- Define Acceptance Criteria for the project, written from the perspective of the customer, in effect act as customer’s Inward-QA for the solution delivered by the vendor.

- Recommend competent vendors, for both product and services, for each part of the RFP.

- Evaluate vendor responses and recommend the most suitable vendor based on cost benefit analysis.

- If required, participate in the project at key stages like Factory Acceptance Testing (FAT), and Site Acceptance Testing (SAT), on behalf of the customer to ensure that the expected value is delivered by the solution.

ATOM Value

There is great value in doing as much upfront requirements definition as possible before a vendor developing the solution is involved.

ATOM acts as your in-house partner in defining these requirements, ensuring that they are aligned with your company culture, budget and time constraints, and current state of technology in the market. This delivers immense value to companies which do not have a large and mature in-house manufacturing IT department

- Uses an established industry standard maturity model (SIRI) to identify solution areas that deliver the highest value for the investment.

- Adds competent bandwidth to the company’s IT department, at a time it is most required, without the cost burden of carrying it when the need is over. During the FEED Consulting phase, ATOM interacts with the external world on behalf of the customer, bringing in an impartial third-party view to the project definition and vendor selection.

- Adds resources that have an understanding of a broad set of technologies required to make a digitization project successful, including Machine Interfacing protocols (e.g. Modbus, Profibus, CANbus, SECS/GEM), Automation (e.g. PLC/SCADA), Plant Floor IT Systems (e.g. OPC, Lab Information Management Systems (LIMS), Manufacturing Execution Systems (MES)), Enterprise IT systems (Production Planning, Warehouse Management, Asset Management/Maintenance, Product Lifecycle Management (PLM)), IIOT systems (Edge Gateway, Cloud/MQTT Gateway), Cloud based IT systems (Dynamic Infrastructure provisioning, Data Lake, Application Server, Web Server, Machine Learning & AI tools)

If the above sounds relevant and interesting, we would be happy to talk to you! Please feel free to send an email to siri@atom-innovation.com